The new filter "failed_antytime"

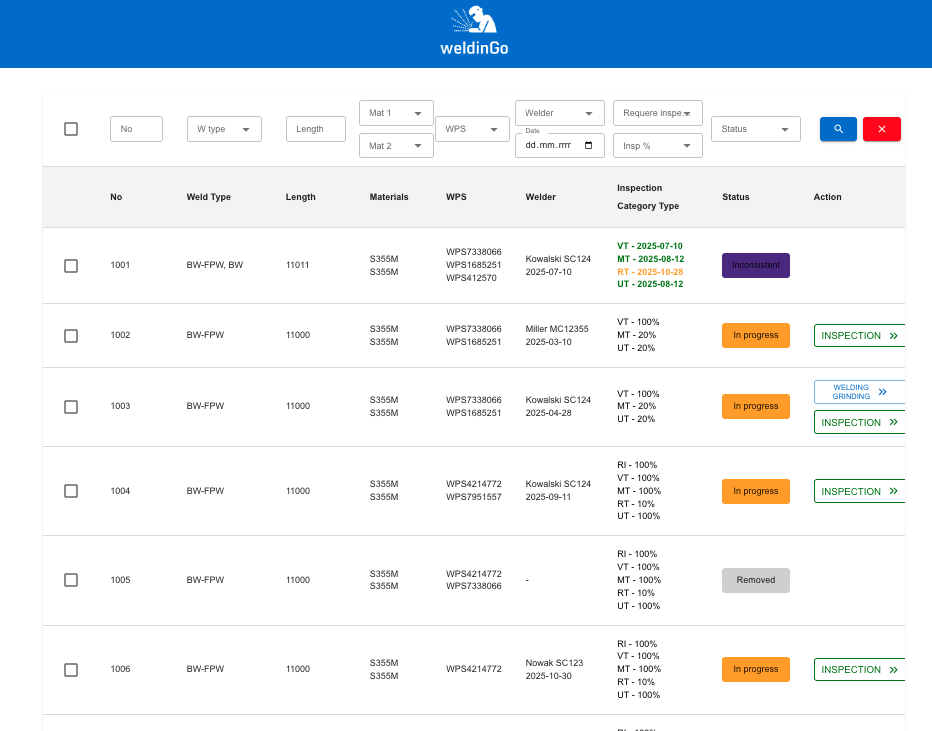

In the weld section, we have added a new “failed_anytime” filter, which allows filtering out welds that have ever had a specified defect and required repair, and are currently already repaired.

Additionally, we have improved filtering within the NDT columns. It is now possible to search for welds by assigning them precise statuses:

- positive (positive),

- failed (negative),

- failed_anytime (negative ever),

- required (required),

- not_required (not required),

skipped (skipped).

Thanks to these enhancements, navigation and data analysis in the weld section are now complete and more intuitive.

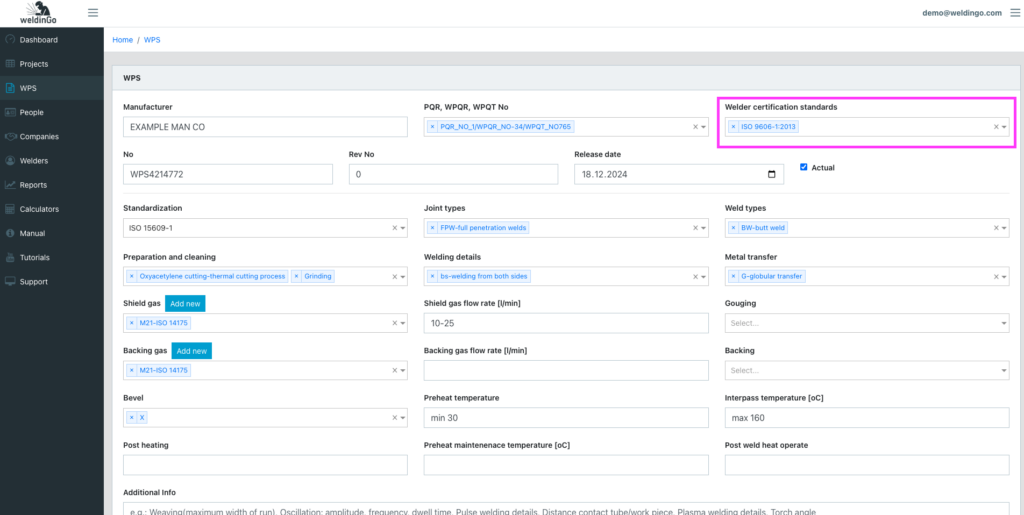

Assigning welder certification standard to WPS

We have introduced another key feature: the ability to assign a specific welder certification standard (e.g., ISO 9606, ASME IX) to a Welding Procedure Specification (WPS).

Thanks to this linkage, the system can precisely validate whether welders assigned to a given weld possess the required and valid qualifications in accordance with the standard specified for that WPS. This enhances control over quality and process compliance.

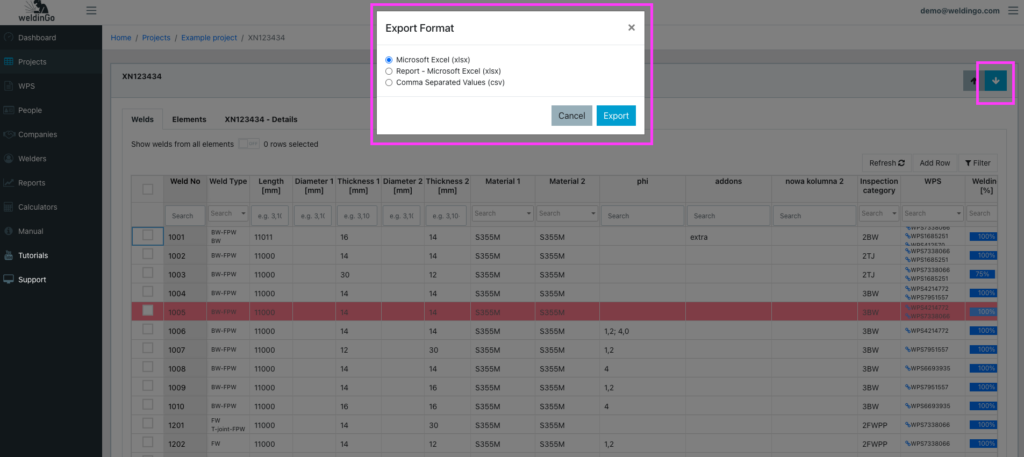

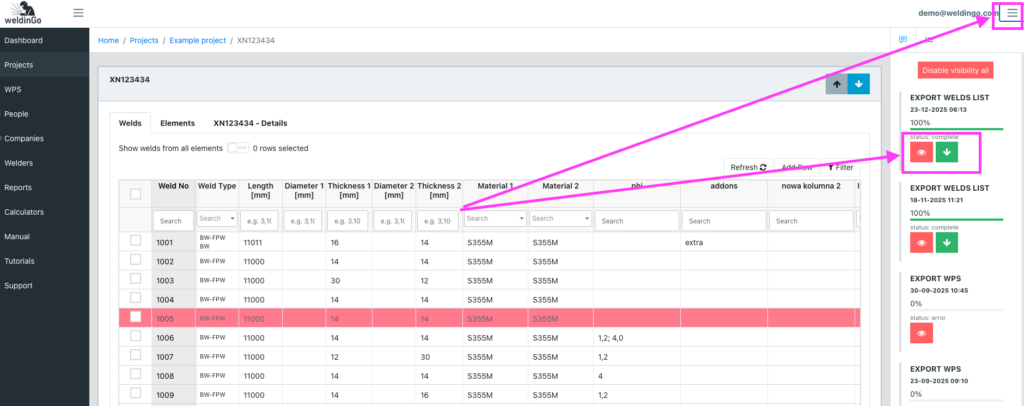

Export welds from the selected section to a file

We have introduced a convenient feature to export weld data for a selected section / element.

The function allows for:

- Downloading to a file all selected welds for the chosen section.

- Choosing one of two formats: Excel (.xlsx) or Comma Separated Values (.csv).

- Additionally, a separate option is available to quickly generate a simplified report in Excel format.

This enables obtaining summaries and conducting external analyses.

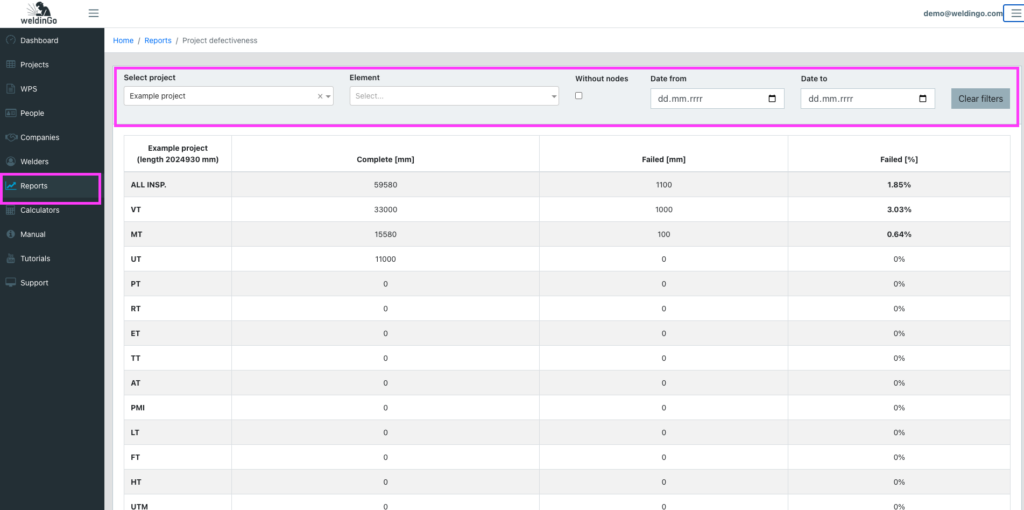

New defect report for projects

In response to our clients’ needs, we have redesigned and significantly expanded the defect report for projects.

Key enhancements:

- Time filtering: The report now enables precise data filtering by a selected date range. This allows the analysis to focus on a specific period.

- Flexible defect summary: We have introduced an advanced option for calculating defects, which offers two possibilities:

- Analysis for a single, selected element only.

- Analysis for the selected element along with all its child (subordinate) elements.

- Filtering by selected projects and elements remains unchanged.

Benefit: The report has become more precise, flexible, and adapted to complex project structures. This allows for more accurate identification of problem sources and better quality management at every project level.

https://demo.weldingo.com/reports/project-defectiveness?project=4

In the Fast App mobile application, dedicated to the quick recording of work progress and NDT test results directly on the production floor, we have recently focused on systematization and optimization.

We have carried out work aimed at fully aligning the functionality and interface of the mobile application with the capabilities available in the main panel (Dashboard). This has made the data flow and user experience more intuitive and consistent across all devices.

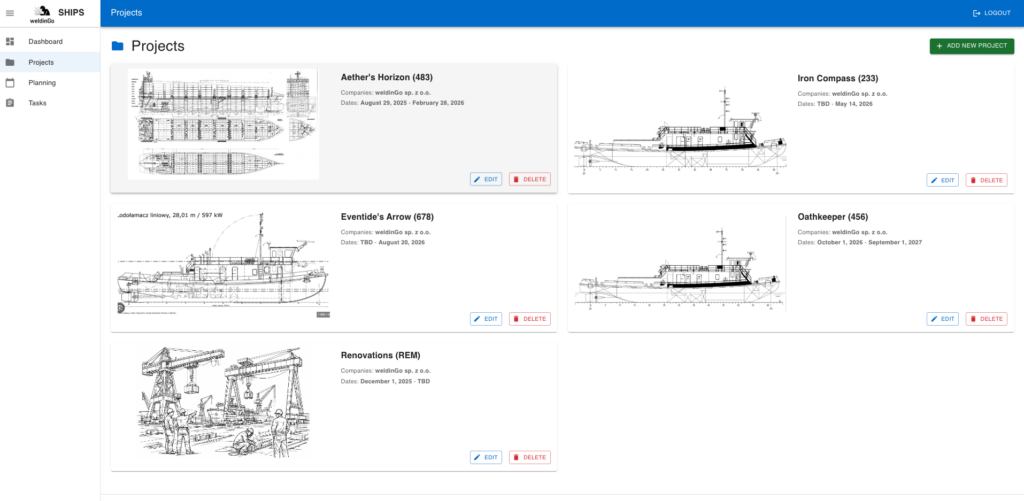

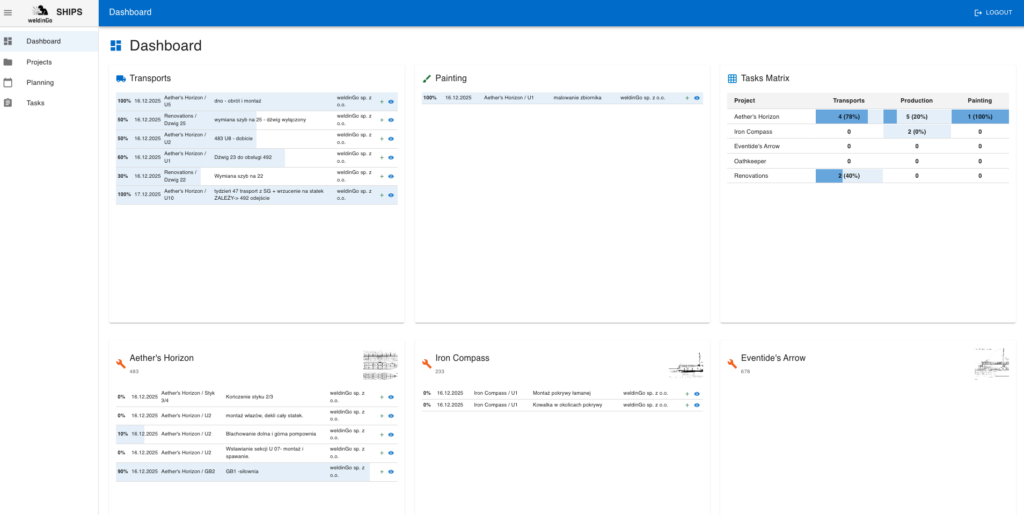

New application: SHIPS

Intensive work is underway on a specialized application dedicated to the shipbuilding industry. In this area, although weld traceability requirements are less stringent, the production process itself remains extremely complex and requires an advanced management tool.

The SHIPS application is based on a proven project tree model, encompassing sections, elements, and units, which the user can freely assemble into blocks using assembly welds. The classic weld assignment system has been retained, but we have enriched it with an additional layer of precision – points.

One of the key innovations is the introduction of a flexible structure manipulation mechanism. It allows for freely combining elements into larger assemblies (such as blocks) and intuitively moving them between different branches of the project, providing unprecedented freedom in planning.

The production of each component has been broken down into fully configurable stages. The user defines these independently – from planning a detailed schedule with dates to assigning specific contractors (companies), following known and proven principles.

The entire system operates based on a detailed task plan, linked to the project, section, and stage, and an advanced analysis of their execution. This enables immediate verification at any moment – for example, comparing the planned dates of a stage with the actual progress of work on the tasks assigned to it.

Most importantly, the SHIPS application introduces a range of unique conveniences that, in our opinion, will revolutionize the current working standards in this type of software. Details of these features and the first demonstration version of the system will be announced at the beginning of 2026.