Dashboard – https://demo.weldingo.com/

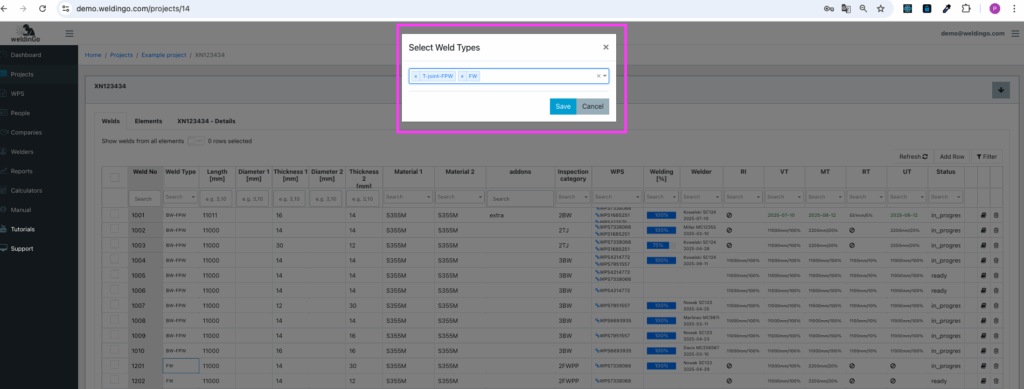

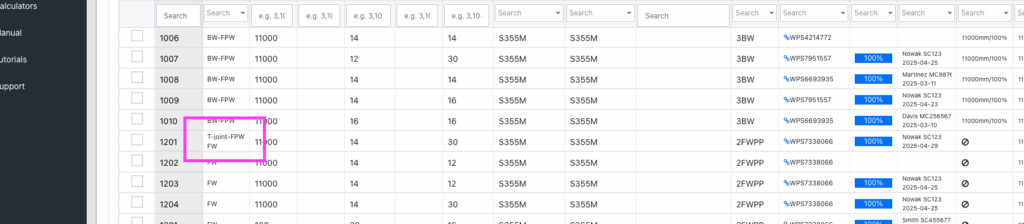

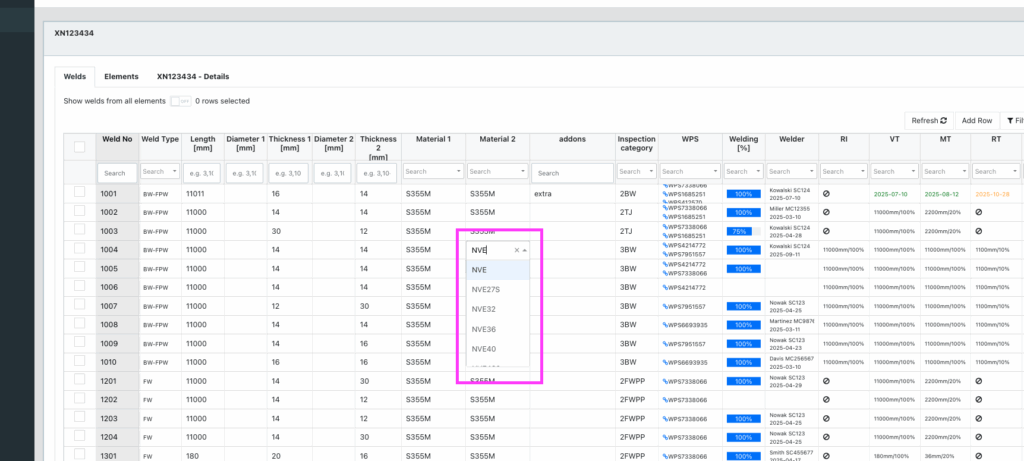

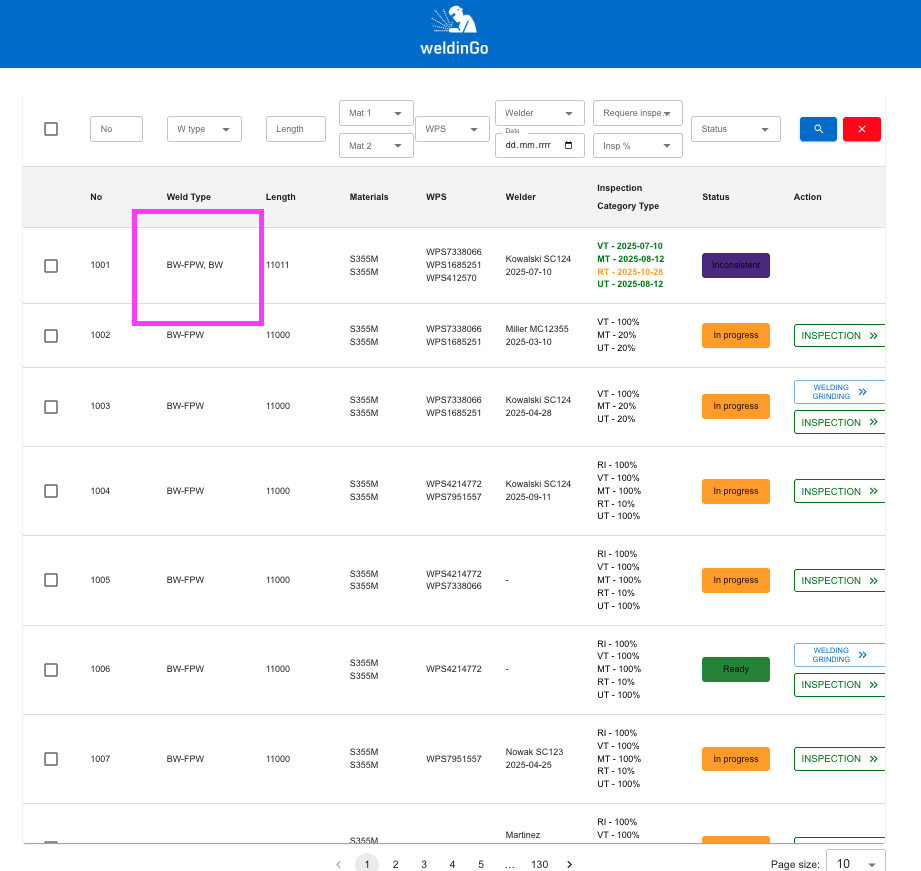

Many weld types for a single weld.

The application has added the ability to assign many weld types to a single weld, for example a weld can be type T-Joint and FW. This will allow for the improvement of algorithms supporting the creation of WPSs and the selection of welders based on available certifications. Additionally, it allows for maintaining compliance with the design during the unification of weld types, which is required by the weldinGo application.

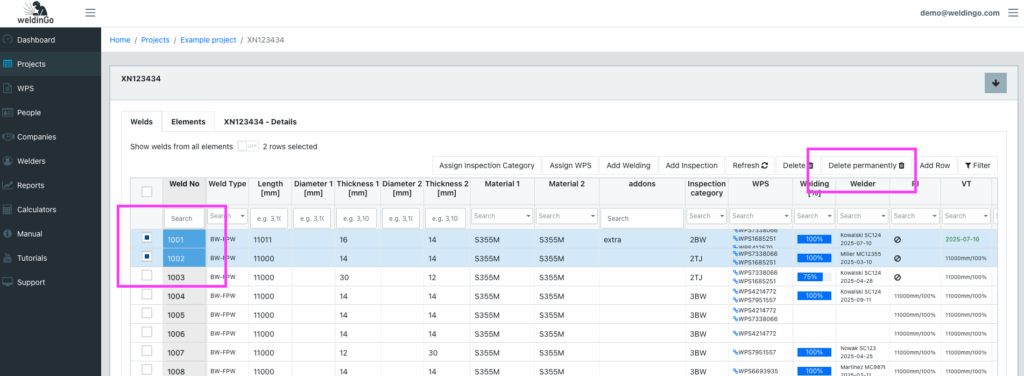

Permanent deletion of welds

The permissions management module has introduced the ability to grant a new permission called “Delete permanently”. This allows a user to select specific welds from the list and completely remove them from the database. Please note that the standard “Delete” only changes the weld status to “removed”, and assigning new permissions requires logging out and logging back into the application.

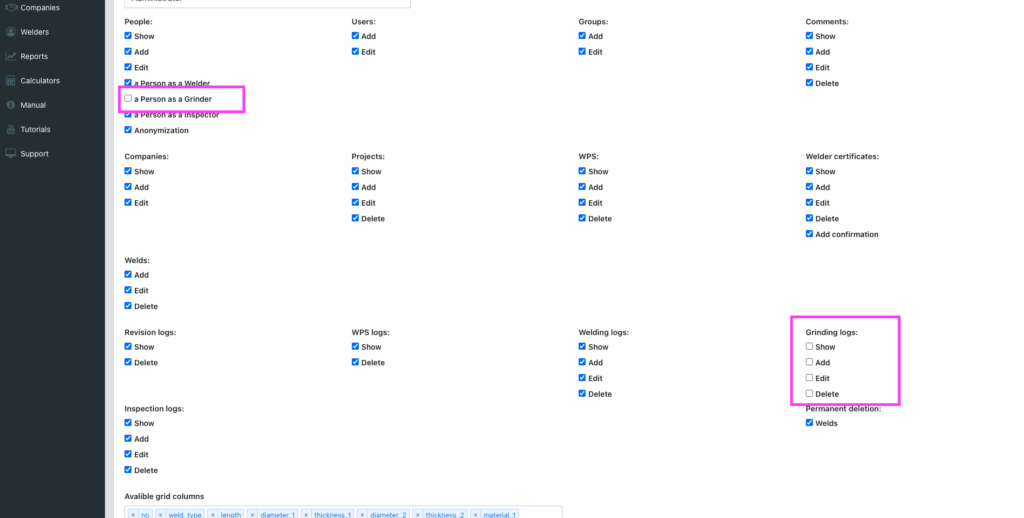

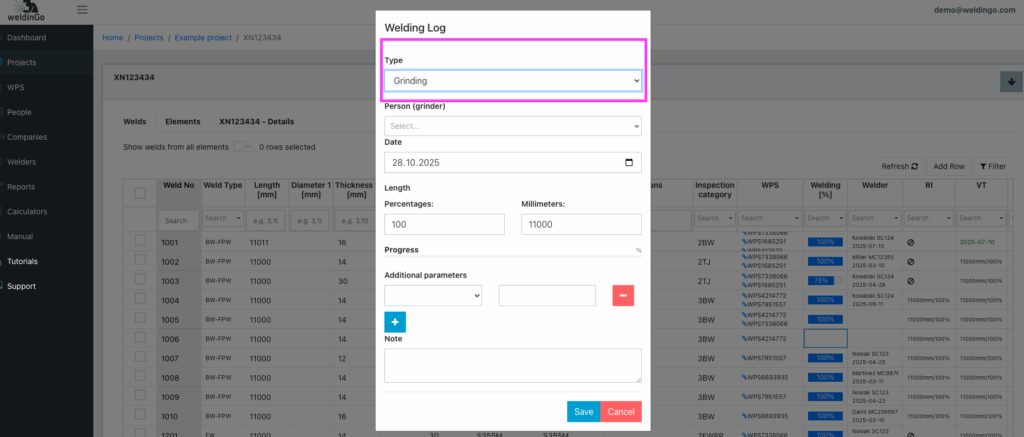

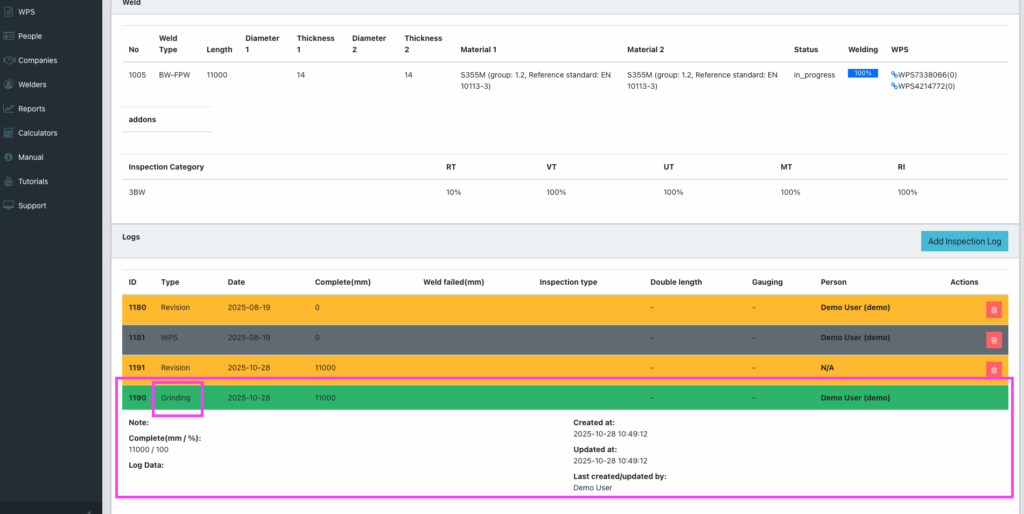

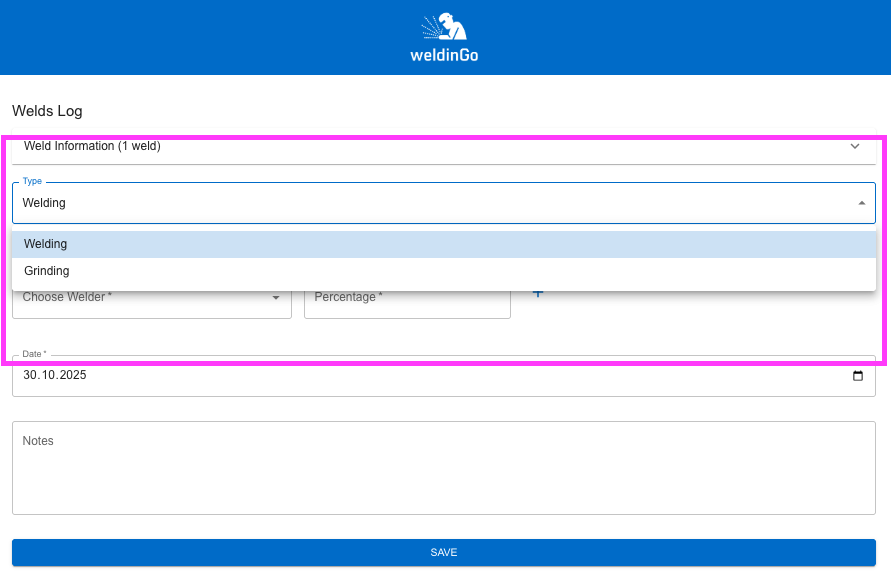

The ability to log a GRINDING event

The application has introduced the ability to record weld grinding operations. This is important to register all information about defects – even those detected during visual testing (VT) that do not require repair by welding, but only by grinding.

This is done by selecting the Welding / Grinding type in the existing welding log window. Welding is always set as the default process.

The entire functionality allows for better identification of weld production processes and the locations where the process – for example, due to the necessity of grinding – becomes extended.

For this functionality, appropriate permissions have been added (which should be assigned to relevant groups) and the ability to designate a group in which grinders are present. Otherwise, after selecting the “Grinding” option in the log window, the list will be empty. Meanwhile, on the log list, these entries are marked in green – similarly to welding – with information about which process was performed.

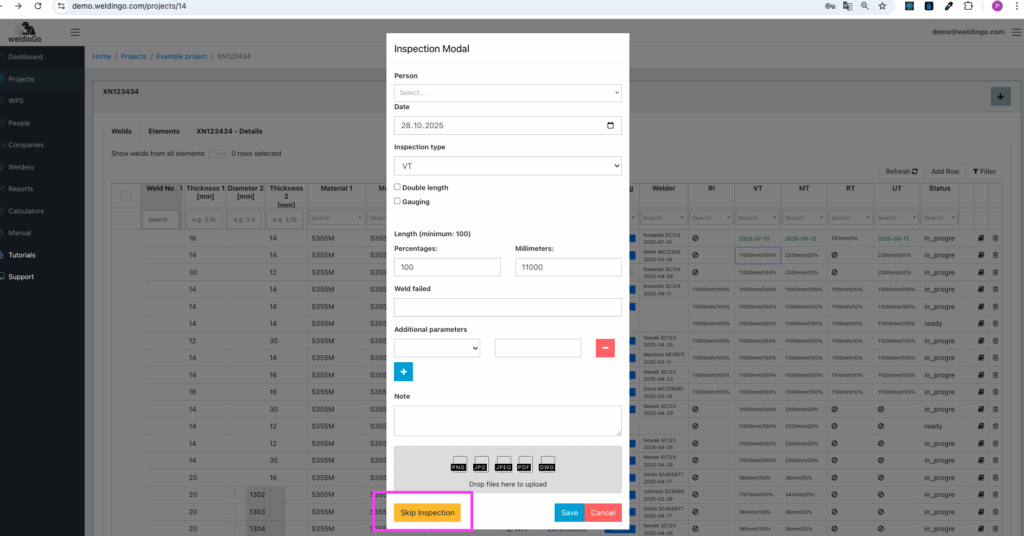

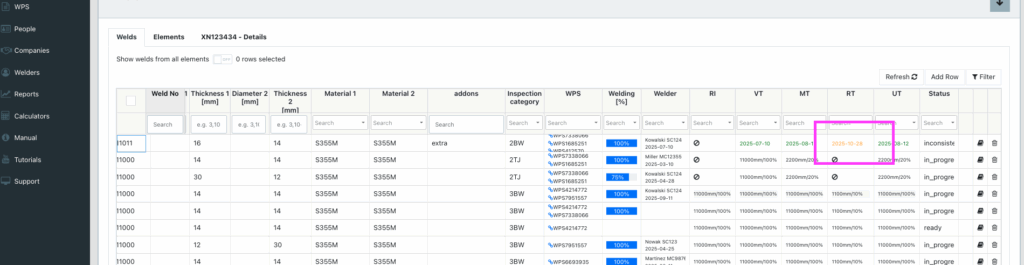

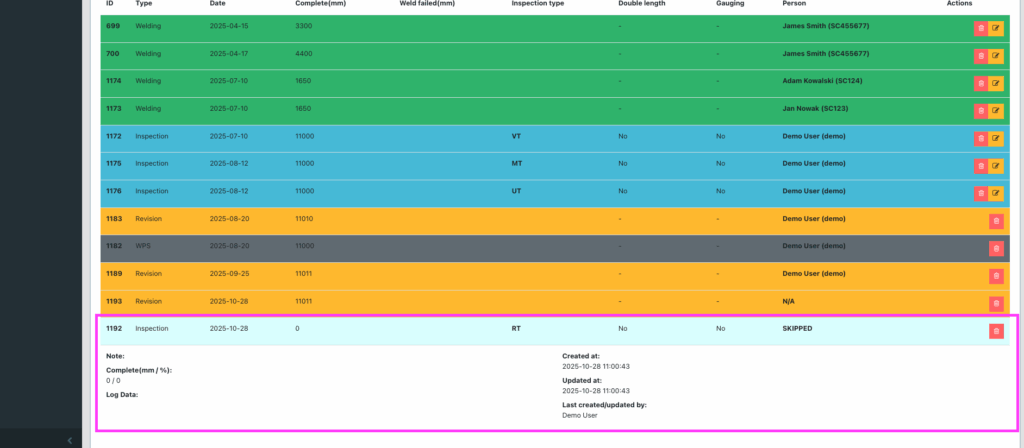

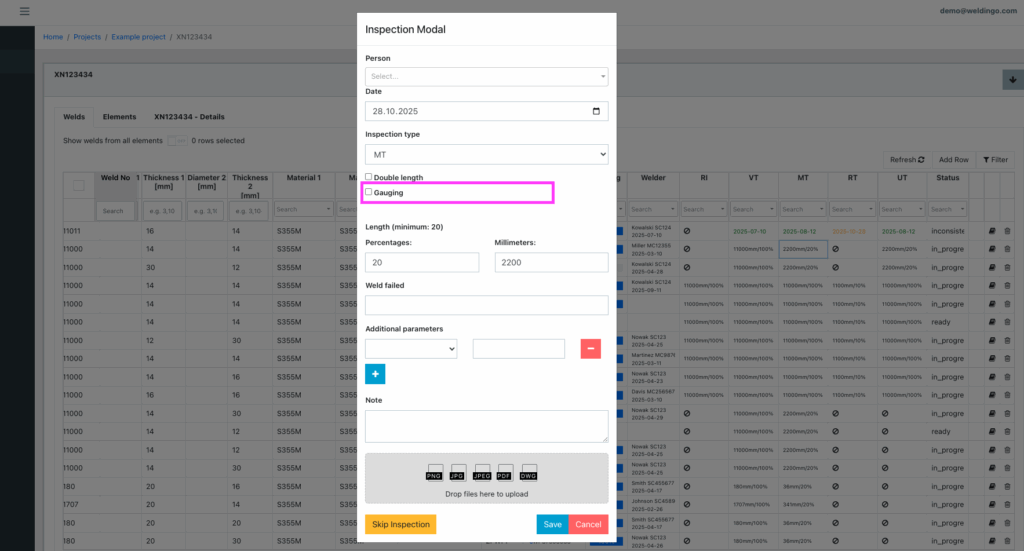

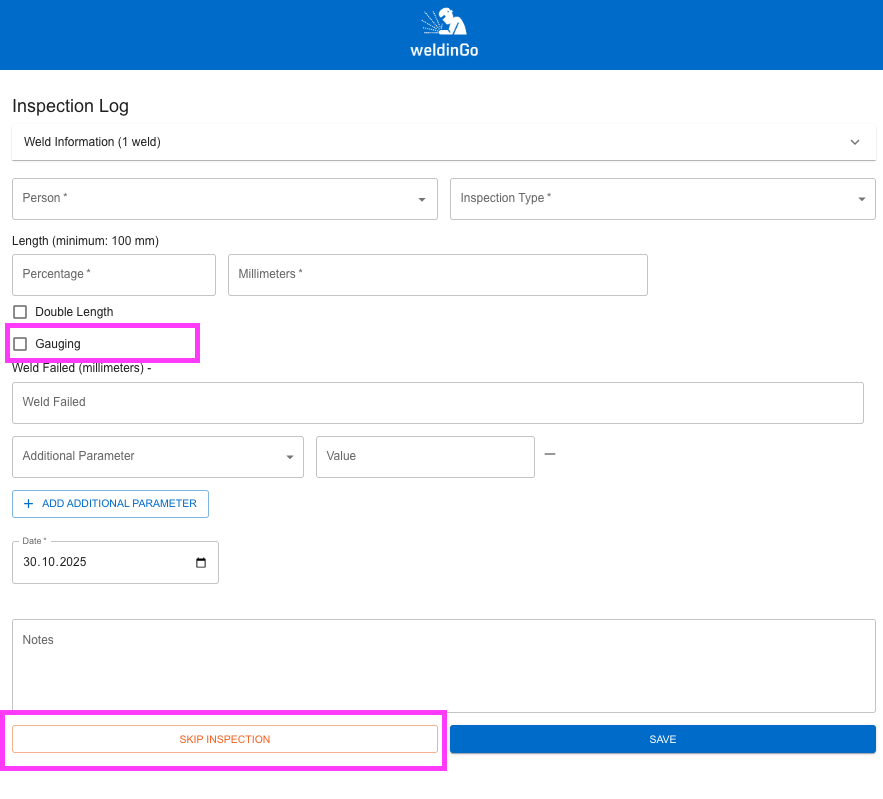

The ability to log a conscious omission of a required test

Due to demand, the application has introduced the ability to skip a test required by the test scope configuration for a weld. This means that in cases where for some welds the UT test is interchangeable with RT and both have the same category, the test can be skipped. This process is very important as it allows for further verification of the weld work progress and ultimately closing it with an OK status.

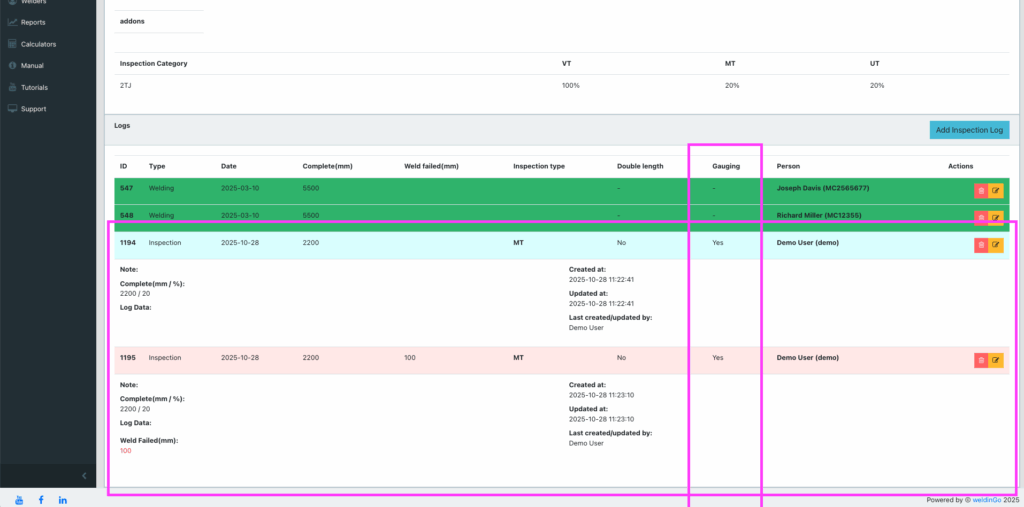

Logging this type of event does not require specifying a person and is done by clicking the “Skip Inspection” button in the test logging window. This action is visible on the weld list as an orange date, and on the event list (logs) these entries are marked with a light blue color.

These entries cannot be edited; they can only be deleted.

Logging additional tests of the gauging type

NDT companies have been given the ability to record additional tests required in the process – for example, weld repairs – which do not affect the appearance of the welding journal. Recording these tests is important from the perspective of later verifying the total length of tests performed by NDT companies. These entries do not affect the process and appearance of the journal, and only appear in the logs marked in light blue or, if a defect is found, in light red with information in the “Gauging” column.

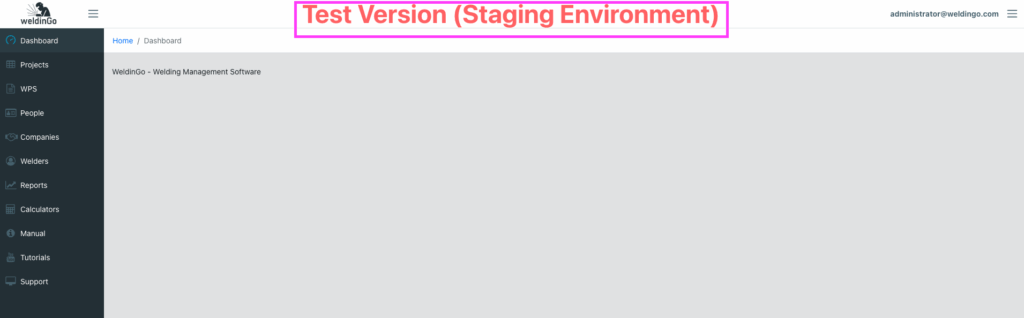

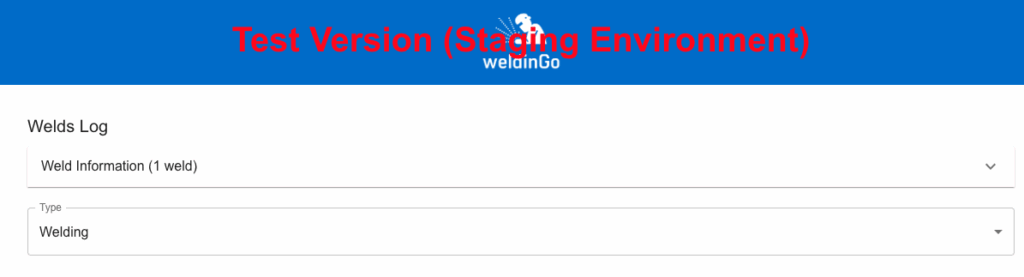

STAGING (sandbox), for companies collaborating on application development.

For companies collaborating with us on application development, staging versions (application test environments – so-called sandboxes) have been launched. These allow for testing and familiarization with newly introduced functionalities before their deployment to production. This enables verification of client expectations and implementation of assumed functions, which ensures the maintenance of high application quality.

These versions, to avoid confusion about the current environment, contain clear information in the header.

Additional material codes based on DNV Ship Steel, AISI (American Iron and Steel Institute) and EN-10025-2

Additional material codes based on DNV Ship Steel, AISI (American Iron and Steel Institute) and EN-10025-2 have been added to the material dictionaries. This was implemented to meet the expectations of new clients.

Fast weldingo app - https://fast-app.demo.weldingo.com/

Multi-weld types, grinding, skip inspection, gauging, and staging

To maintain application consistency, the mobile app now also includes:

- Support for assigning multiple weld types.

- The ability to skip inspections.

- Recording of grinding events by selecting the type on the existing welding registration screen (welding remains the default process).

- Recording of additional gauging-type tests.

- Version information for companies that also have a pre-production test version of the application.

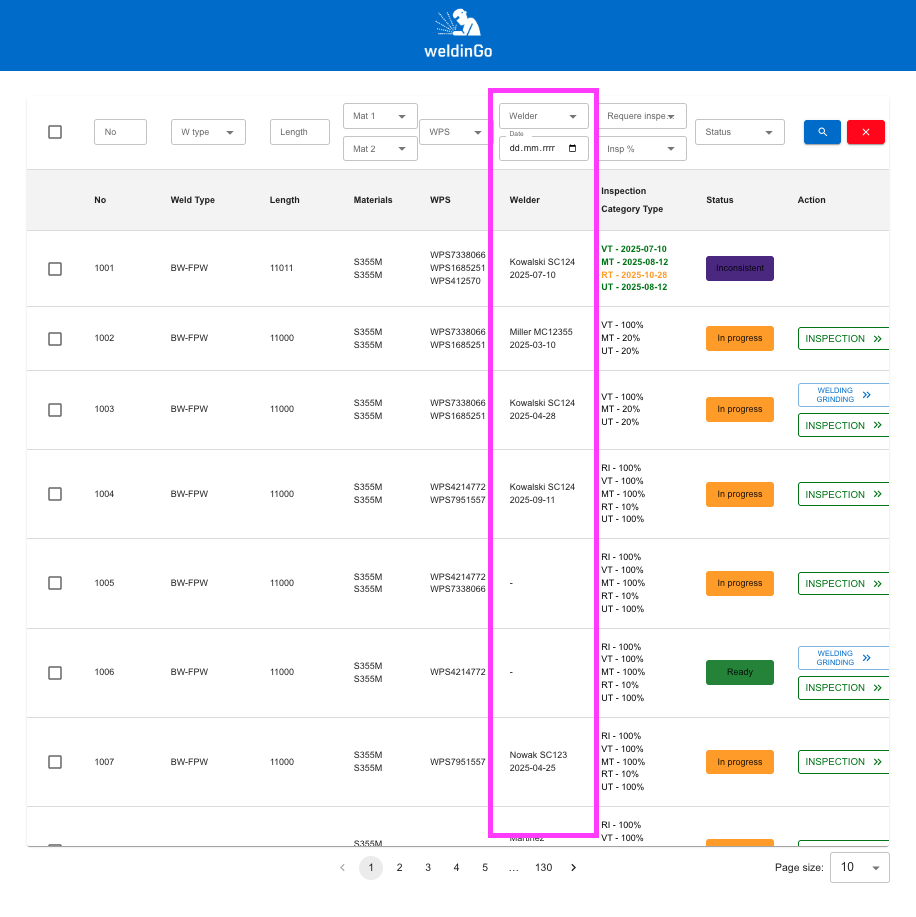

Information about the last welding

A new column has been added to the application, displaying information about the last welder and the welding date, along with corresponding filters. Adding this column should significantly facilitate the QA departments in identifying welds for testing.